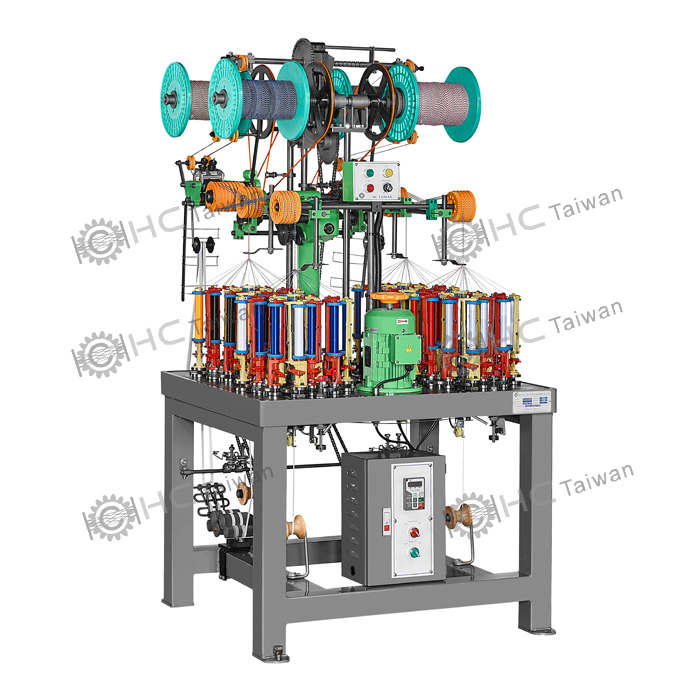

Looking for a shoelace braiding machine or a high speed braiding machine manufacturer?

- Our textile cords braiding machines meet diverse industrial needs.

- Designed for efficiency and accuracy, these machines handle the production of shoelaces, elastic straps, and various textile cords.

Models available include :

- RA-48-1×2(90): Suitable for high-speed shoelace and cord production.

- RA-16-4(90): Ideal for manufacturing durable textile cords.

- FAA-17-4(80): Specializes in elastic strap braiding.

Key features :

- Advanced engineering for stable, precise operation.

- Consistent output for mass production.

- User-friendly controls and low maintenance requirements.

As a high speed braiding machine manufacturer based in Taiwan, we provide equipment trusted by textile businesses worldwide.

For inquiries about shoelace braiding machines or custom specifications, contact us for more details.

Who Benefits from Textile Cord Braiding Machines?

Textile cord braiding machines are essential for manufacturers seeking efficient ways to produce shoelaces, elastic straps, and various textile cords. These machines are ideal for:

- Shoe factories needing consistent, durable shoelaces

- Apparel manufacturers producing elastic cords for sportswear, masks, or accessories

- Textile businesses requiring custom cord designs for bags, home goods, or industrial applications

Common Questions Answered

What is a shoelace braiding machine?

A shoelace braiding machine is equipment designed to weave yarns or threads into shoelaces, ensuring uniform diameter, strength, and appearance.

How do I choose a high speed braiding machine manufacturer?

Look for manufacturers offering robust construction, advanced engineering, and models tailored for different cord types. Consider support, export experience, and machine lifespan.

What types of cords can be made?

- Shoelaces for sneakers, boots, and dress shoes

- Elastic straps for sportswear, masks, and luggage

- Decorative cords for apparel and accessories

Key Features of Textile Cord Braiding Machines

- High Output: Machines like the RA-48-1×2(90) and RA-16-4(90) deliver fast production rates, supporting large-scale orders without sacrificing consistency.

- Precision Engineering: Ensures each cord meets strict dimensional and strength requirements.

- User-Friendly Controls: Intuitive interfaces reduce operator training time and support easy adjustments.

- Low Maintenance: Designed for minimal downtime and long service intervals.

- Versatility: Models such as the FAA-17-4(80) handle both standard and elastic cords, adapting to a wide range of textile needs.

Why Choose a High Speed Braiding Machine Manufacturer from Taiwan?

Manufacturers based in Taiwan, such as HSIANG CHUAN, are recognized for their innovation and export expertise. Their machines are widely used by textile businesses worldwide for:

- Consistent, high-speed output

- Long operational life

- Adaptability to custom requirements

Real-World Use Cases

- A sportswear company producing elastic cords for face masks increased output by 40% after upgrading to a high speed braiding machine.

- Shoe factories report fewer defects and improved lace uniformity with advanced shoelace braiding machines.

- Textile suppliers meet diverse client specifications with customizable machine settings.