Cable Braiding Machine: Essential Equipment for Modern Cable Manufacturing

Who Needs a Cable Braiding Machine?

A cable braiding machine is designed for manufacturers and engineers who need to produce cables, wires, hoses, and tubes with enhanced durability, flexibility, and electromagnetic shielding. This equipment is widely used in industries such as electronics, automotive, aerospace, telecommunications, and industrial automation.

-

Fully automated braiding process for stable and uniform results

-

Minimal manual operation required, reducing labor costs

-

Suitable for a wide range of cable sizes and types

-

Robust construction ensures long-lasting machine performance

-

High-speed operation boosts production output

-

Designed for various applications: coaxial cables, wire harnesses, tubes, and hoses

-

Compatible with different materials, including stainless steel wire and textile cords

-

Adjustable settings for precise braiding patterns and tension control

-

Easy maintenance and user-friendly interface

-

Ideal for cable manufacturers aiming to increase productivity and product consistency

Why Choose Our Cable Braiding Machine?

-

Versatile tool for diverse cable manufacturing needs

-

Consistent braiding quality for improved cable durability

-

Supports mass production without compromising accuracy

-

Reduces downtime with reliable, automated operation

Applications:

-

Electrical cable shielding

-

Coaxial cable reinforcement

-

Automotive wiring harnesses

-

Hydraulic and pneumatic hose protection

-

Fiber optic cable construction

Contact HSIANG CHUAN MACHINERY CO., LTD. for more details about our cable braiding machine and how it can optimize your cable production line.

Common Questions Answered

-

What is a cable braiding machine used for?

-

How can I automate the braiding process for coaxial cables or wire harnesses?

-

Which machine is best for producing braided tubes, hoses, or stainless steel wire coverings?

-

What features should I look for in a cable braiding machine for high-volume production?

Key Features of the Cable Braiding Machine

-

Fully Automated Operation: The braiding process is automated, reducing manual labor and ensuring consistent results.

-

Versatile Cable Compatibility: Handles a wide range of cable sizes and types, including coaxial cables, wire harnesses, tubes, and hoses.

-

High-Speed Performance: Designed for manufacturers aiming to increase production rates without sacrificing consistency.

-

Robust Construction: Built for continuous operation in demanding industrial environments.

-

Minimal Manual Intervention: Streamlines workflow and reduces the risk of human error.

Use Cases

-

Coaxial Cable Manufacturing: Achieve uniform braiding for improved signal shielding.

-

Wire Harness Production: Automate the braiding of complex harnesses for automotive or aerospace applications.

-

Braided Tubes and Hoses: Produce flexible, reinforced hoses for hydraulic or pneumatic systems.

-

Stainless Steel Wire Braiding: Create protective coverings for cables exposed to harsh conditions.

Product Range

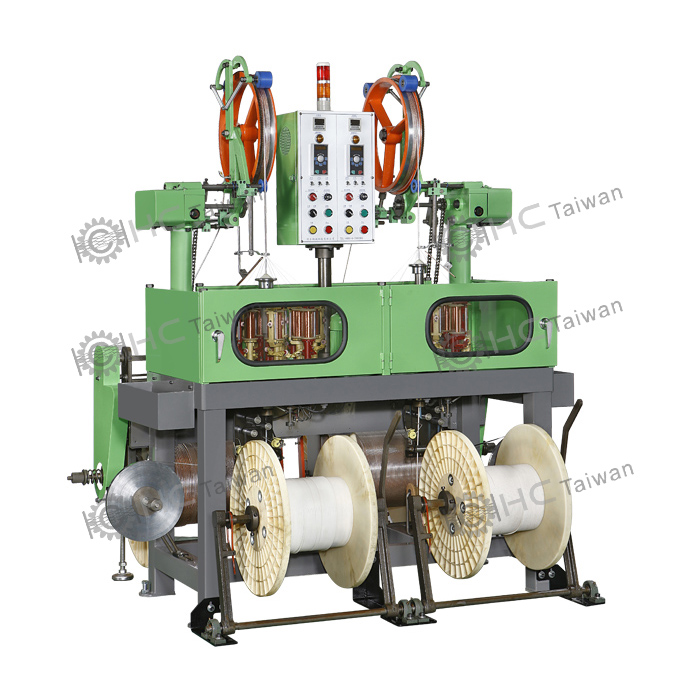

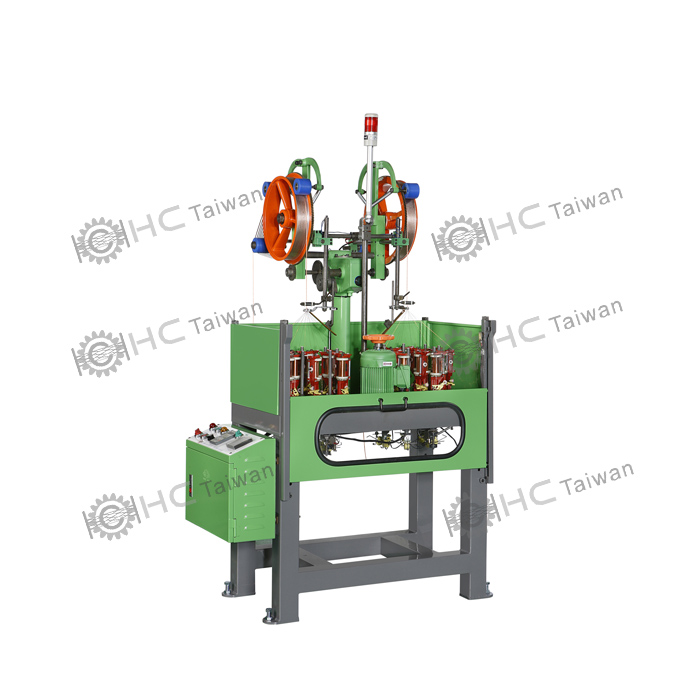

Wire & Cable Braiding Machines

-

RCA-36-1(110): Suitable for standard wire braiding tasks.

-

RCA-16-1×2(110): Designed for dual braiding operations.

-

FLA-13-2(90): Ideal for fine wire applications.

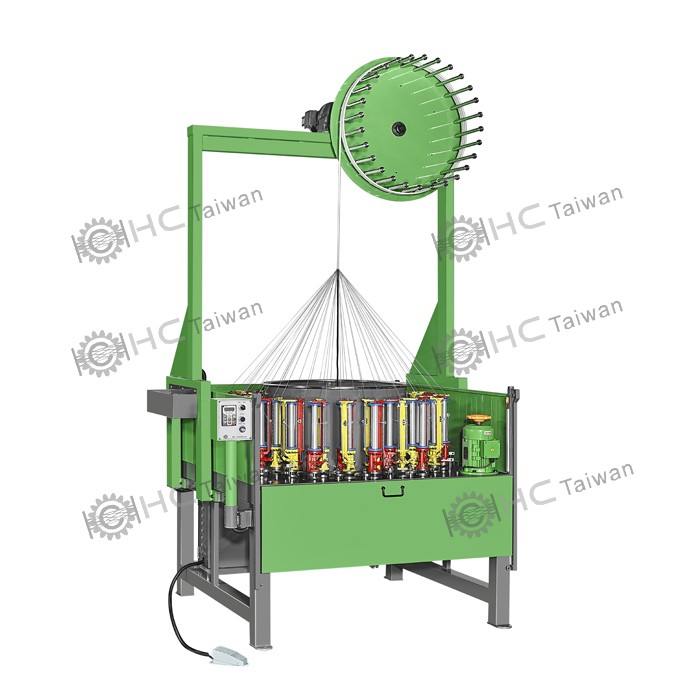

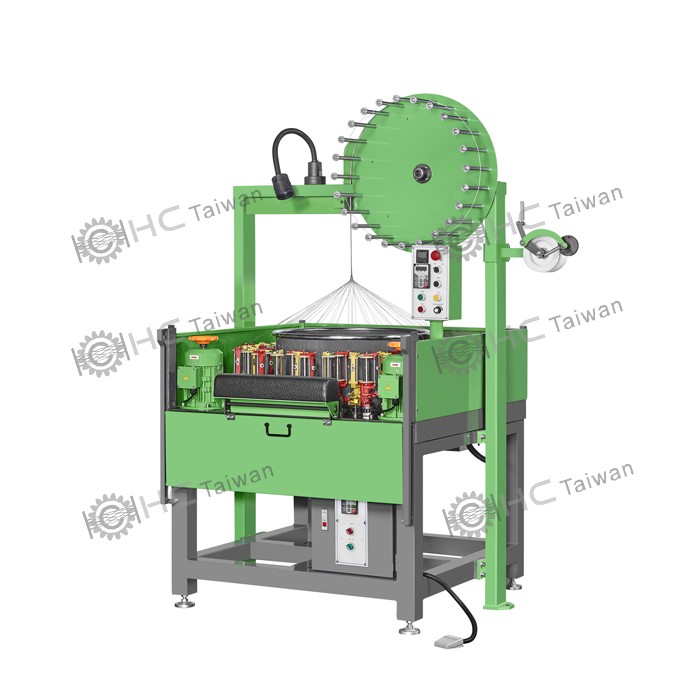

Harness Braiding Machines

-

RBF-48-1(130Ⅱ)S: For complex wire harnesses.

-

RMA-48-1(90): Supports high-volume harness production.

Additional Equipment

-

Textile Cords